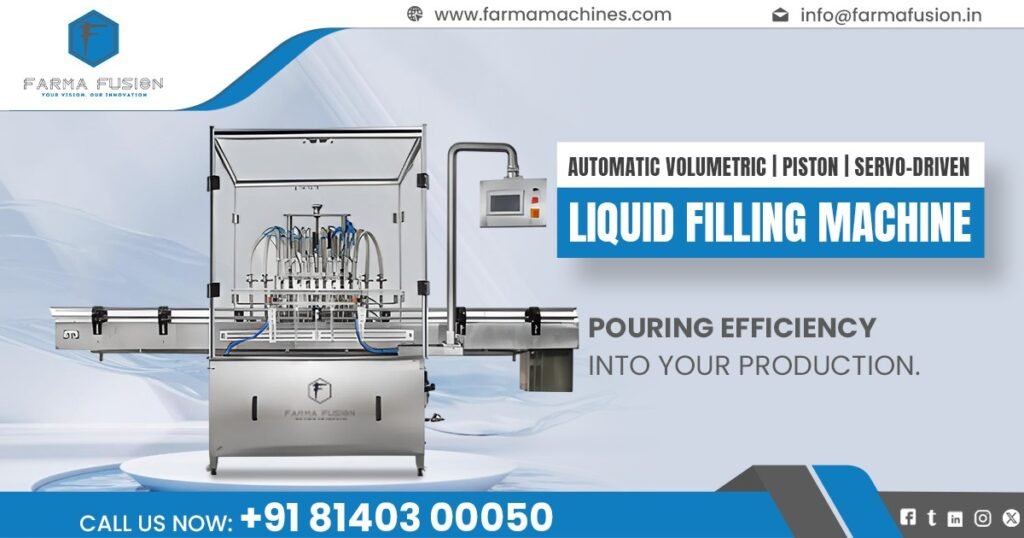

Farma Fusion is a Manufacturer, Supplier and Exporter of Versatile Liquid Filling Lines for Every Viscosity and Container in United States.

Our Manufacturer unit is based in Ahmedabad, Gujarat, India.

At Farma Fusion, we specialize in engineering Versatile Liquid Filling Lines that cater to a wide range of viscosities and container types.

We design our automated filling systems to deliver precision, efficiency, and adaptability for filling water-like solutions, thick syrups, oils, creams, and gels across industries.

Our automated filling lines deliver high throughput and adaptability, ideal for startups, SMEs, and large-scale manufacturing operations.

A Liquid Filling Line automates dispensing liquids into containers like bottles, tubes, jars, and vials with optimal accuracy.

These systems perform container feeding, liquid filling, capping, and labeling — streamlining production in pharmaceutical, cosmetic, and food industries.

What makes our filling lines “versatile” is their ability to handle different viscosities and packaging formats with precision and speed.

Process:

The liquid filling process typically involves:

Container Feeding: Operators load containers onto the conveyor automatically or manually.

Filling Station: The system dispenses the product into containers using piston, peristaltic, or gravity filling mechanisms, depending on viscosity.

Nozzle Control: Anti-drip or diving nozzles ensure clean filling and prevent spillage.

Capping (Optional): Integrated capping units secure caps onto filled containers.

Labeling (Optional): Operators can add front, back, or wrap-around labeling after the filling process.

Quality Check & Discharge: Inspectors examine the filled containers and move them to the next line.

Features:

Multiple nozzles for faster throughput.

Automatic bottle feeding and outfeed conveyors.

No-bottle-no-fill safety mechanism.

Anti-drip and diving nozzle mechanisms.

CIP/SIP (Clean-in-Place / Sterilize-in-Place) support.

Tool-less changeover between container sizes.

Custom integration with capping, labeling, and shrink-wrapping systems.

User-friendly HMI for operator control.

Applications:

Pharmaceuticals: Syrups, suspensions, oral drops, antiseptics.

Cosmetics & Personal Care: Lotions, shampoos, oils, creams.

Food & Beverages: Juices, sauces, extracts, flavored water.

Chemicals: Disinfectants, pesticides, lubricants.

Ayurveda & Nutraceuticals: Herbal tonics, drops, oil blends.

Homecare Products: Liquid detergents, surface cleaners, sanitizers.

FAQs – Frequently Asked Questions:

Q1. What types of liquids can your filling lines handle?

Our machines can handle everything from water-thin liquids to thick gels and creams, including oils, syrups, suspensions, and pastes.

Q2. Can the machine fill different types of containers?

Yes, our systems are compatible with bottles, vials, jars, tubes, ampoules, and more. Changeover is fast and tool-free.

Q3. Are your machines GMP and FDA compliant?

Absolutely. All contact parts are SS 316L and designed for sanitary operations in compliance with GMP, FDA, and CE standards.

Farma Fusion is a Manufacturer and Exporter of Versatile Liquid Filling Lines for Every Viscosity and Container in United States Including California, Texas, Florida, New York, Pennsylvania, Illinois, Ohio, Georgia, North Carolina, Michigan, New Jersey, Virginia, Washington, Arizona, Tennessee, Massachusetts, Indiana, Missouri, Maryland, Wisconsin, Colorado, Minnesota, South Carolina, Alabama, Louisiana.

For more information and inquiries, feel free to contact us.